No products in the cart.

Sale

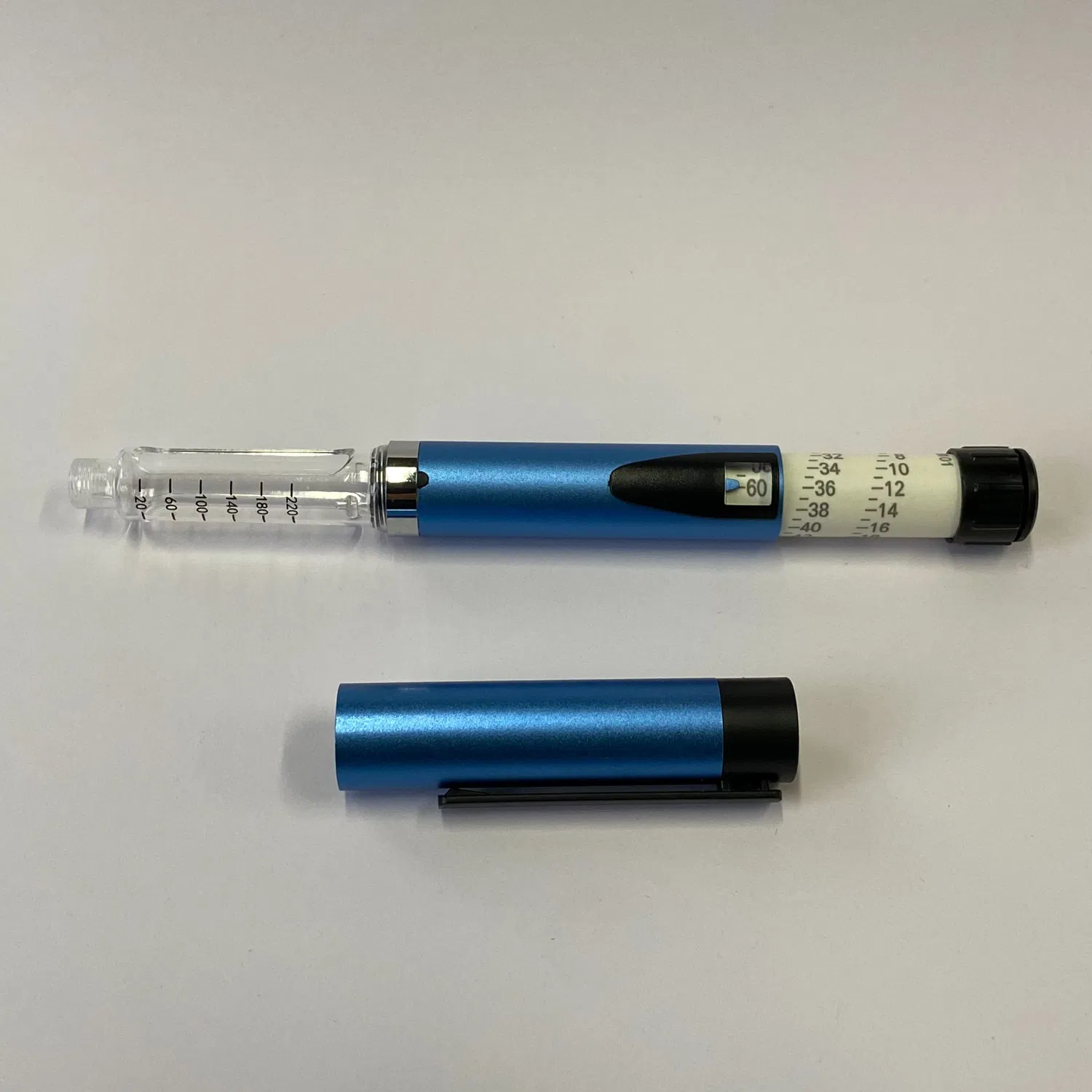

Insulin Injector Pen – Factory customizes and wholesales reusable precision models in various colors.

Original price was: $4.00.$3.00Current price is: $3.00.

Insulin Injector Pen is a reusable precision product manufactured with borosilicate glass and durable structural components. This Insulin Injector Pen supports multiple specifications and is supplied directly from a China factory for low-cost wholesale and global B2B export.

Description

Product Description

Insulin Injector Pen is a reusable precision product developed for stable liquid containment and controlled handling requirements. Manufactured in a professional China factory, this Insulin Injector Pen combines borosilicate glass with durable structural components to ensure consistency, cleanliness, and long-term usability across multiple application scenarios.

The structure of this Insulin Injector Pen is based on a round glass body produced through advanced bottle-blowing technology. The smooth surface and uniform thickness support stable performance, while the hard material characteristic helps maintain shape integrity during repeated use. Each Insulin Injector Pen is supplied with standardized components, allowing flexible configuration according to different project or procurement needs.

From a manufacturing perspective, this Insulin Injector Pen follows strict process control from raw material selection to final packaging. COE 5.0 neutral borosilicate glass is used to achieve reliable physical properties, and all components are prepared in separated packaging formats to support clean handling and efficient logistics. This structure is suitable for large-scale production and continuous export supply.

Designed with global B2B markets in mind, the Insulin Injector Pen supports multiple specifications and packaging options. Factory direct manufacturing enables low-cost wholesale pricing, stable lead times, and OEM flexibility. With mature export experience, this Insulin Injector Pen is suitable for distributors, brand owners, and bulk buyers seeking consistent quality and long-term supply from China.

Product Specifications

| Attribute | Description |

|---|---|

| Product Type | Insulin Injector Pen |

| Design | Reusable, precision structural design |

| Material | High-quality borosilicate glass with auxiliary components |

| Glass Type | COE 5.0 neutral borosilicate glass |

| Glass Property | USP Type I |

| Shape | Round |

| Surface | Smooth, uniform thickness |

| Graduation | Without Graduation |

| Type | Roll |

| Cap Type | Rubber stopper with aluminum cap |

| Sealing Structure | Rubber stopper sealing |

| Flexibility | Hard |

| Technics | Bottle blowing |

| Color | Clear |

| Available Specifications | 1.5ml / 1.8ml / 3ml |

| Component Supply | Glass barrel, rubber component, aluminum cap (separately packaged) |

| Packaging Option | PP tray inner box / export carton |

| Transport Package | Cartons |

| Sample Policy | Free samples available |

| Sample Lead Time | 1 day |

| Delivery Time | Within 5 days for regular models |

| OEM Service | Custom structure, packaging, and surface handling supported |

| Trademark | SNAIL GLASS |

| Origin | Shandong, China |

| HS Code | 70109090 |

| Production Capacity | 200,000 PCS per day |

| Manufacturing Mode | China factory direct production |

| Export Supply | Global B2B wholesale |

Structure & Material Details

The Insulin Injector Pen is constructed with a focus on material stability, structural consistency, and scalable manufacturing. The main body is produced from COE 5.0 neutral borosilicate glass tube, selected for its uniform wall thickness and reliable physical characteristics. This glass material supports stable forming during the bottle-blowing process and maintains dimensional consistency across large production batches.

The round glass barrel of the Insulin Injector Pen features a smooth internal and external surface, which supports clean handling and reduces material residue during repeated use. The hard structural property helps the product maintain its shape integrity under standard handling and packaging conditions, making it suitable for long-distance transportation and bulk export.

Each Insulin Injector Pen is supplied as a modular structure. Standard configuration includes a glass barrel, a rubber sealing component, and an aluminum cap with an internal seal. All components are prepared and packaged separately, allowing buyers to select full sets or individual parts based on procurement needs. This modular supply structure also supports OEM customization and flexible inventory management.

From a manufacturing and packaging perspective, the Insulin Injector Pen follows controlled production and handling procedures. Components are processed and prepared in clean production environments, then packed into PP tray inner boxes or nest boxes for RTU options. Multiple inner boxes are consolidated into export-grade cartons to ensure protection and efficiency during global B2B shipping.

Designed for factory-scale output, this Insulin Injector Pen structure supports high-volume production while maintaining consistent material quality. With a daily capacity of up to 200,000 pieces, the product is suitable for long-term wholesale cooperation, stable export supply, and international distribution from China.

Mechanism of Action

The Insulin Injector Pen operates based on a precision structural mechanism designed for controlled liquid containment and stable output behavior. Its function relies on the coordinated interaction between the glass barrel, sealing components, and external structural elements, forming a closed and consistent internal environment during operation.

At the core of the Insulin Injector Pen mechanism is the smooth inner surface of the COE 5.0 borosilicate glass barrel. This surface finish supports uniform liquid movement and minimizes resistance during repeated handling. The round geometry and consistent wall thickness help maintain balanced internal pressure, contributing to predictable and repeatable performance.

The sealing mechanism of the Insulin Injector Pen is achieved through a rubber sealing component combined with an aluminum cap structure. This configuration creates a reliable physical seal that helps maintain stability during storage, transport, and repeated use. The hard structural characteristics of the materials support long-term dimensional consistency without deformation under standard operating conditions.

From an engineering perspective, the Insulin Injector Pen is designed to support modular assembly and disassembly. Components are produced with standardized tolerances, allowing smooth integration and replacement when required. This mechanism supports flexible configuration for different specifications and simplifies large-scale production, quality inspection, and export packaging.

Overall, the mechanism of the Insulin Injector Pen emphasizes precision, durability, and repeatability. The design is optimized for factory manufacturing, bulk handling, and long-distance transportation, making it suitable for global B2B supply chains and long-term wholesale cooperation.

Applications

The Insulin Injector Pen is widely used across industrial and commercial scenarios that require precision liquid containment, standardized structure, and repeatable handling performance. Its stable material composition and modular design make it suitable for multiple non-consumer and B2B-oriented applications.

In industrial production environments, the Insulin Injector Pen is commonly applied in liquid filling system testing, packaging line calibration, and equipment compatibility verification. The consistent internal structure and standardized specifications support accurate evaluation during machinery setup and process optimization.

For laboratory and technical development settings, the Insulin Injector Pen is suitable for formulation trials, material compatibility assessment, and container performance testing. The borosilicate glass construction provides reliable physical characteristics, supporting repeated handling during development and validation stages.

In OEM and private-label projects, the Insulin Injector Pen is frequently used as a base component for customized solutions. Manufacturers and brand owners can integrate the product into their own systems, apply customized surface treatments, or combine it with alternative components according to project requirements.

The Insulin Injector Pen is also applicable in bulk export and distribution chains where standardized packaging, stable transport performance, and scalable supply are required. Factory-direct production and flexible configuration options make it suitable for long-term wholesale cooperation and international B2B supply.

Packaging Options

The Insulin Injector Pen offers multiple packaging configurations to support different logistics and storage requirements. Individual PP tray inner box packaging is designed to provide clean separation and protection during handling and short-distance transport. For bulk orders, multiple PP tray boxes are securely packed into export-grade cartons to improve loading efficiency and reduce transit risk. An RTU option packed in a nest box is also available, supporting standardized handling and streamlined downstream operations. All packaging solutions are optimized for factory-scale output and international B2B shipment.

Shipping Guarantee

Each Insulin Injector Pen is prepared with export-grade secure packaging to ensure stability during international transportation. For small quantity orders, express delivery options such as DHL, UPS, FedEx, and TNT are available to support fast turnaround requirements. Bulk orders can be shipped by air or sea, depending on cost efficiency and delivery timelines. Logistics solutions are optimized based on destination, volume, and buyer preferences to ensure smooth international B2B delivery. Factory export experience helps minimize delays and handling risks.

Trade Assurance

The Insulin Injector Pen is supplied through China factory direct manufacturing, ensuring transparent production control and competitive wholesale pricing. A stable quality control system is implemented throughout raw material selection, production, and packaging processes. Standardized procedures support consistency across large-volume orders and long-term supply programs. The factory is experienced in global export operations and documentation handling. Long-term B2B wholesale cooperation is supported with stable capacity and responsive coordination.

Payment Support

To support international buyers, the Insulin Injector Pen offers flexible payment options suitable for global B2B transactions. Credit card payments are accepted for convenience and faster processing. Traditional methods such as T/T (Telegraphic Transfer), L/C, D/P, and D/A are supported for structured trade arrangements. Cryptocurrency payments are also available for buyers seeking alternative settlement methods. Multiple payment options help improve transaction efficiency and cross-border cooperation.

Disclaimer

This Insulin Injector Pen is intended for industrial, laboratory, and material handling use only. It is supplied as a structural and packaging-related product rather than a consumer-use item. All operations, handling, and integration should follow applicable regulations and professional standards relevant to the buyer’s industry. Buyers are responsible for ensuring proper use within their own systems and environments. The manufacturer does not assume responsibility for applications outside the agreed scope.

Additional information

| Weight | 1.6 kg |

|---|---|

| Dimensions | 53 × 48 × 53 cm |

Q1: Can I request samples before placing a bulk order?

Yes, samples of the Insulin Injector Pen are available for evaluation. Samples are provided free of charge, while express shipping costs are borne by the buyer. Sample preparation time is typically within 1 day. This allows buyers to verify structure, material quality, and packaging before bulk procurement.

Q2: Do you support OEM or customized production?

Yes, OEM and customization services are supported for the Insulin Injector Pen. Custom options may include specifications, packaging configurations, and surface handling. Buyers can provide drawings or reference samples to initiate customization. The factory supports stable OEM production for long-term B2B projects.

Q3: What is the standard delivery time for orders?

For regular models of the Insulin Injector Pen, production is typically completed within 3–5 working days after payment confirmation. Customized or OEM orders require a longer lead time, usually around 30–35 working days. Delivery schedules may vary depending on order quantity and packaging requirements. The factory coordinates production planning to ensure timely shipment.

Q4: What shipping methods are available?

The Insulin Injector Pen can be shipped by express, air, or sea according to order size and urgency. Express services such as DHL, UPS, FedEx, and TNT are recommended for small orders. For bulk shipments, air or sea transport is suggested to optimize cost efficiency. Logistics solutions are selected based on destination and buyer preferences.

Q5: How are quality issues handled after delivery?

All Insulin Injector Pen products are supplied under a defined quality control system. If quality issues are identified after receipt, buyers are encouraged to contact the supplier promptly with relevant details. Solutions are handled according to agreed trade terms and cooperation arrangements. Timely communication helps ensure efficient resolution and long-term cooperation.

Q6: Can the packaging be customized for branding purposes?

Yes, the packaging of the Insulin Injector Pen can be customized to meet branding or logistics requirements. Options include inner PP tray boxes, nest boxes, and export cartons. Buyers can request custom printing, labeling, or tray arrangements. This supports both OEM projects and large-scale B2B distribution.

Q7: What is the minimum order quantity (MOQ)?

The factory can accommodate flexible MOQ arrangements for the Insulin Injector Pen, ranging from small sample orders to large wholesale batches. MOQ depends on specifications, packaging, and customization requirements. Buyers are encouraged to discuss order details with the sales team for precise planning.

Q8: How can I ensure stable supply for long-term cooperation?

The Insulin Injector Pen is manufactured with daily production capacity up to 200,000 pieces. The factory maintains inventory and production planning to ensure continuous supply for B2B clients. Long-term cooperation agreements can be arranged with predictable lead times and volume commitments.

Q9: Are there any safety or handling recommendations?

While the Insulin Injector Pen is designed for industrial and technical liquid handling, proper handling and storage are recommended to maintain product integrity. Avoid dropping or applying excessive external force to prevent damage. Follow standard industrial material handling practices to ensure longevity.

Q10: Can multiple specifications be mixed in one order?

Yes, the Insulin Injector Pen supports mixed-specification orders. Buyers can select different capacities (1.5ml, 1.8ml, 3ml) or packaging options in a single shipment. This flexibility is convenient for OEM projects, testing purposes, or diversified B2B distribution.

Reviews

There are no reviews yet.